Most erectors and riggers accumulate an assortment of lifting beams during the course of time. Lifting tackle and Spreader Beams are.

Our extensive range of lifting beams and lifting tackle is design and constructed with the best raw materials and procured from the trustworthy and certified vendors of the market.

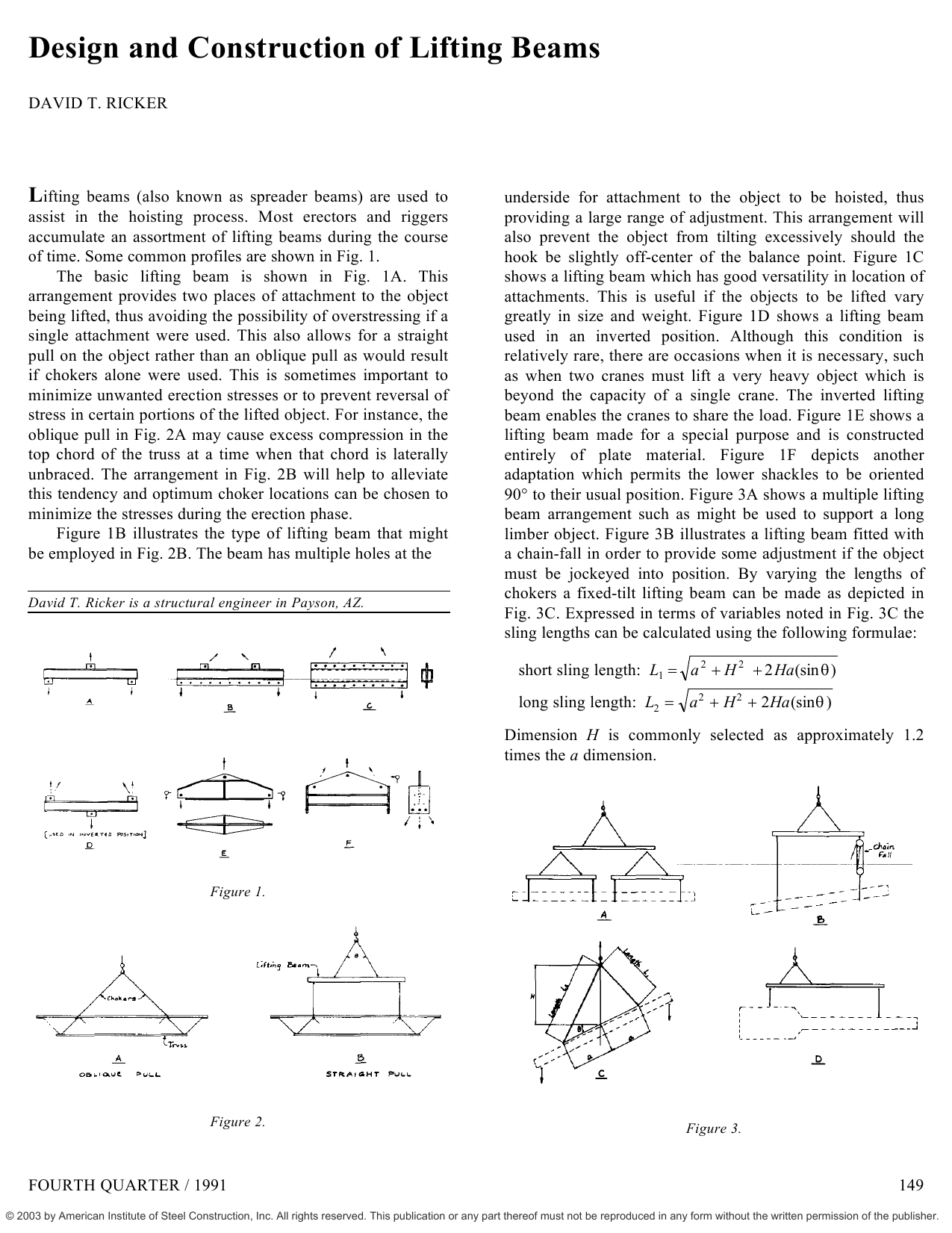

. By using BTH-1 for designing lifting beams the different failure modes of the beam will be addressed and appropriate safety factors will be applied to the design dependent on the intended use or. In the article he states the 4 failure modes to check are. Some common profiles are shown in Fig.

The basic lifting beam is shown in Fig. FSE Safe focuses more on quality and thats why our wide range of adjustable spreader beams and tackles is recognized more due to their qualitative features. Design of Stiffened Plate Lifting Beams The American Society of Mechanical Engineers has published a new standard for the design of below-the-hook lifting devices.

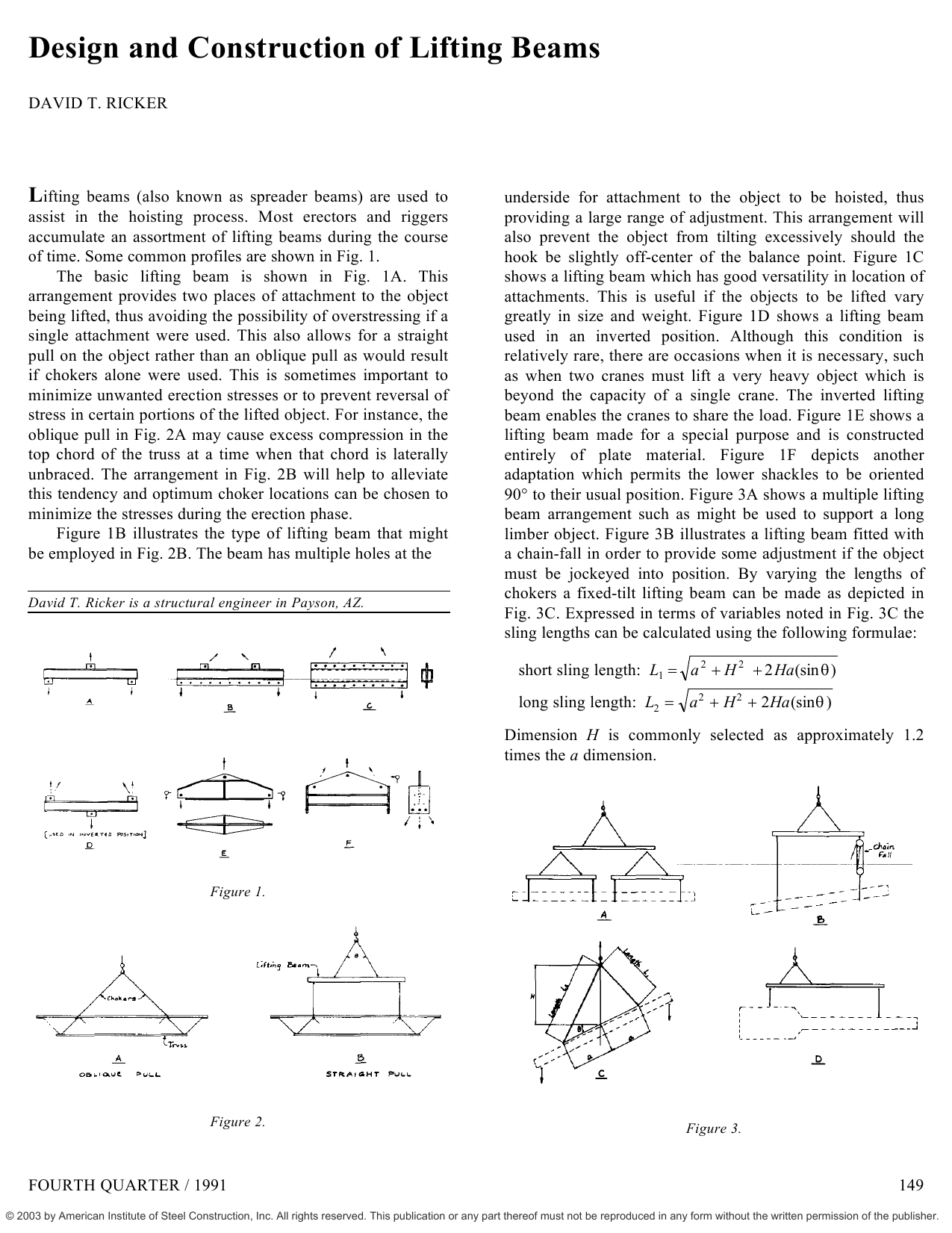

Lifting beams also known as spreader beams are used to assist in the hoisting process. DESIGN AND CONSTRUCTION OF LIFTING BEAMS ENGINEERING The main topic of the following pdf is focused on DESIGN AND CONSTRUCTION OF LIFTING BEAMS ENGINEERING nevertheless it didnt shut the. One type of lifting device that is common in construction and that is not specifically addressed in the standard is the stiffened plate lifting beam.

The lifting beam enables the user to. Lifting beams also known as spreader beams are used to assist in the hoisting process. Along with stress buckling is also a critical factor in lifting beams that must be addressed in.

Basic design decisions can have a considerable effect on the overall buildability and cost of a building. Design issues that are applicable to this type of lifting beam are lateral-torsional buckling combined tensile and shear stresses in the regions around pin-loaded holes connections among the built-up elements of. BDesign of Below-the-Hook Lifting Devices - ASME BTH-1-2008 American Society of Mechanical Engineers.

2 Forces on a lifting beam. Beams suspended by wire rope or other flexible elements such as lifting beams are not restrained as such. The basic lifting beam is shown in Fig.

AISC Manual of Steel Construction ASD Ninth Edition 1989 1. Focusing on modern commercial and industrial buildings this publication provides. Design and Construction of Lifting Beams Engineering Journal American Institute of Steel Construction Vol.

An Overview of ASME BTH-1 spreader bars and lifting beams When planning to design lifting beams or any other below-the-hook lifting devices there are many aspects that must be considered beyond finding materials that meets a few basic engineering calculations. Most erectors and riggers accumulate an assortment of lifting beams during the course of time. One type of lifting device that is common in construction and that is not specifically addressed in the standard is the stiffened plate lifting beam.

The equations commonly used in practice for the design of beams are based on the assumption that the members are restrained against lateral displacement and twist at the ends of the unbraced length. RICKER Lifting beams also known as spreader beams are used to underside for attachment to the object to be hoisted thus assist in the hoisting process. We can see that it has a lifting eye at its top in the middle while the eyes below are used to connect the slings to the lifted object.

A lifting beam is a solid or fabricated m etal beam suspended from a hoistcrane or from forks of a forklift designed to pro vide multiple lifting points. The following paper has numerious examples. A lifting beam has a simple design consisting of a beam with a single attachment point centered on the top side of the beam for connecting to a crane hoist or other lifting machine.

I am currently making a spreadsheet to determine the capacity of lifting lugs using the processes laid out by David T. There are other factors that need to be addressed. Design and construction of lifting beams chan myae id 5dcdb97934b9f pre ered prefab steel structure supermarket china made in lifting load case structural ering general discussion eng structural performance of 800 mpa high strength steel members 2 journal paper ctbuh papers.

Spreader beams are universally applied gear which is widely used in various types of lifting operations onshore and offshore. Determine the normal capacity of a beam and divide the load by 2 to get the factor of safety of 5 A36 material. There are two basic approaches to this.

Ad Shop A Wide Selection Of Material Handling Equipment To Easily Move Lift More. ADesign and Construction of Lifting Beams - David T. 28 Nov 18 1836.

Design and Construction of Lifting Beams DAVID T. Spreaders can be made in modules which are assembled into the configuration required. This is also in line with the load ratings for other components of the lifting assembly such as slings shackles etc.

In this article we will explore the design of a basic spreader beam and see what design checks are needed to establish the suitability of a spreader beam for particular lifting operation. Ricker originally published in American Institute of Steel Construction AISC - Design Journal 4th Quarter 1991. Some common profiles are shown in Fig.

Lifting beams also known as spreader beams are used to assist in the hoisting process. Design and Construction of Lifting Beams. Design issues that are applicable to this type.

Design and Construction of Lifting Beams. Lifting beams can have adjustable lifting points which can be moved along the beam to suit the particular load. This standard defines allowable stress structural design requirements for lifting devices used in construction and general industry in conjunction with cranes derricks and other.

Lifting beams convert lifting loads into bending forces on the beam. Tension Failure at the sides of the holes 2. Most erectors and riggers providing a large range of adjustment.

Most erectors and riggers accumulate an assortment of lifting beams during the course of time. Designing a spreader beam for lifting. Thus the buckling behavior of suspended beams can.

Design and Construction of Lifting Beams Engineering Journal American Institute of Steel Construction Vol. The design of lifting beams must meet specific calculation requirements per BTH-1 to verify that the design will be safe and effective for its intended below-the-hook lifting application. Lifting beams also known as spreader beams are used to assist in the hoisting process.

If we resolve the forces we can immediately see that the lifting beam will be primarily under bending stress see figure 2. Lifting beams are designed to take bending loads. The right choices can help to reduce conflict in the design and construction process and to reduce the likelihood of expensive remedial work.

Design and Construction of Lifting Beams. Omer Blodgett Design of Welded Structures 1966 2. Ricker in his article Design and Construction of Lifting Beams published by AISC in 1991.

Most erectors and riggers accumulate an assortment of lifting beams during the course of time. Ricker Design and Construction of Lifting Beams Engineering Journal 4th Quarter 1991. Some lifting beams may have two bails in order to engage two crane or hoist hooks.

Lifting beams and spreaders can also be designed for multi-purpose applications.

Design And Construction Of Lifting Beams Semantic Scholar

The Why And How Of Designing A Lifting Beam Thenavalarch

The Why And How Of Designing A Lifting Beam Thenavalarch

Design And Construction Of Lifting Beams Semantic Scholar

Designing A Spreader Beam For Lifting Thenavalarch

Design And Construction Of Lifting Beams Semantic Scholar

Design And Construction Of Lifting Beams

Pdf Design And Construction Of Lifting Beams Chan Myae Academia Edu

0 comments

Post a Comment